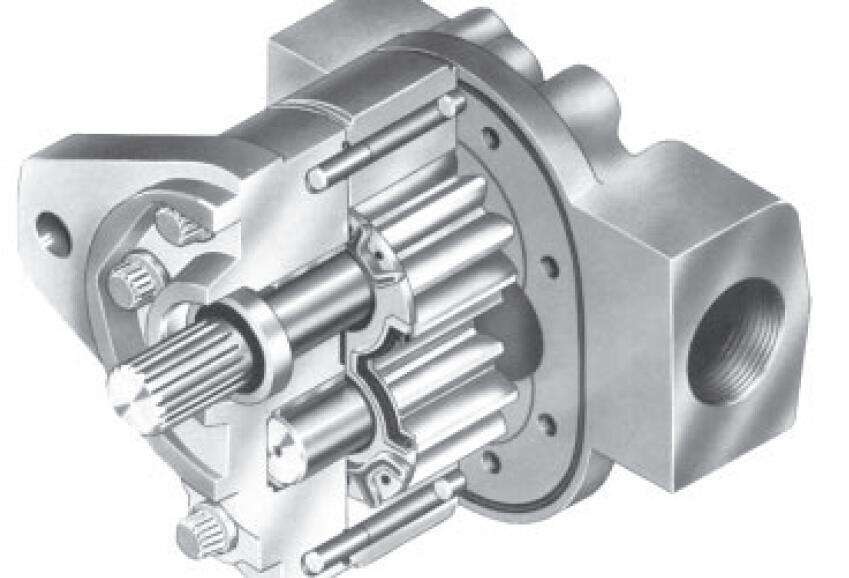

Polyether ether ketone (PEEK) is a semi crystalline, thermoplastic aromatic polymer material and the main variety of polyaryletherketone (PAEK) series polymers. PEEK molecular chains contain a large number of benzene rings, which have excellent physical and chemical properties such as heat resistance, wear resistance, fatigue resistance, radiation resistance, peel resistance, and creep resistance. Its two ether bonds and carbonyl group bring flexibility and excellent processability, and are widely used in aerospace, automotive, electronic and electrical, medical, and other industrial fields.

PEEK injection molding is not completely the same as general plastic injection molding. PEEK material has a very high melting temperature and viscosity. If ordinary injection molding machines and auxiliary equipment are used to inject PEEK material without experience, it will cause different degrees of defects in the injection molded products, affecting the performance of PEEK products. Especially, the mechanical properties, chemical properties, electrical properties, fatigue resistance, stress, and deformation of PEEK injection molded products will be affected to varying degrees. When using PEEK injection molded products under special requirements, it is necessary to consider the instability or failure of PEEK injection molded parts due to the above reasons during operation. More stringent improvement requirements have been put forward for the entire injection molding system for PEEK precision injection molded parts.

Our contact information is as follows:

Company Address: 1st Floor, Building 7, No. 85 Sanda Road, Pujiang Town, Minhang District, Shanghai, China

Company Phone: 021-54840839